Lingerie is amongst the more complex product segments to be found in the fashion industry, as it must fulfill several performance criteria ranging from functionality, well-fitting, aesthetics, washability and of course comfort, which often can only be achieved with synthetic materials such as polyester, nylon and elastics. Bras especially are considered to be one of the most complicated garments to make and can easily consist of more than 30 different parts. This also makes lingerie a challenging product segment when it comes to sustainability: redesigning lingerie with circularity in mind is therefore a complex task.

So, how can one design out of waste when it comes to lingerie, swimwear and bodywear?

While implementing textile waste management measures in four major lingerie mills and manufacturers in the framework of a Private-Public-Partnership project for sustainable development, we identified big quantities of perfectly reusable waste materials ranging from warp knits such as tricot and raschel; tulle, embroidery, lace, jacquards, rips and jerseys. Materials applied in lingerie are often very delicate and prone to tear and defects, which leads to higher textile waste quantities during the production processes.

Via our on-site textile waste assessment, the identified main points of waste generation appeared during the fabric production, manual quality control of ready-made fabrics, the cutting process and customer rejects.

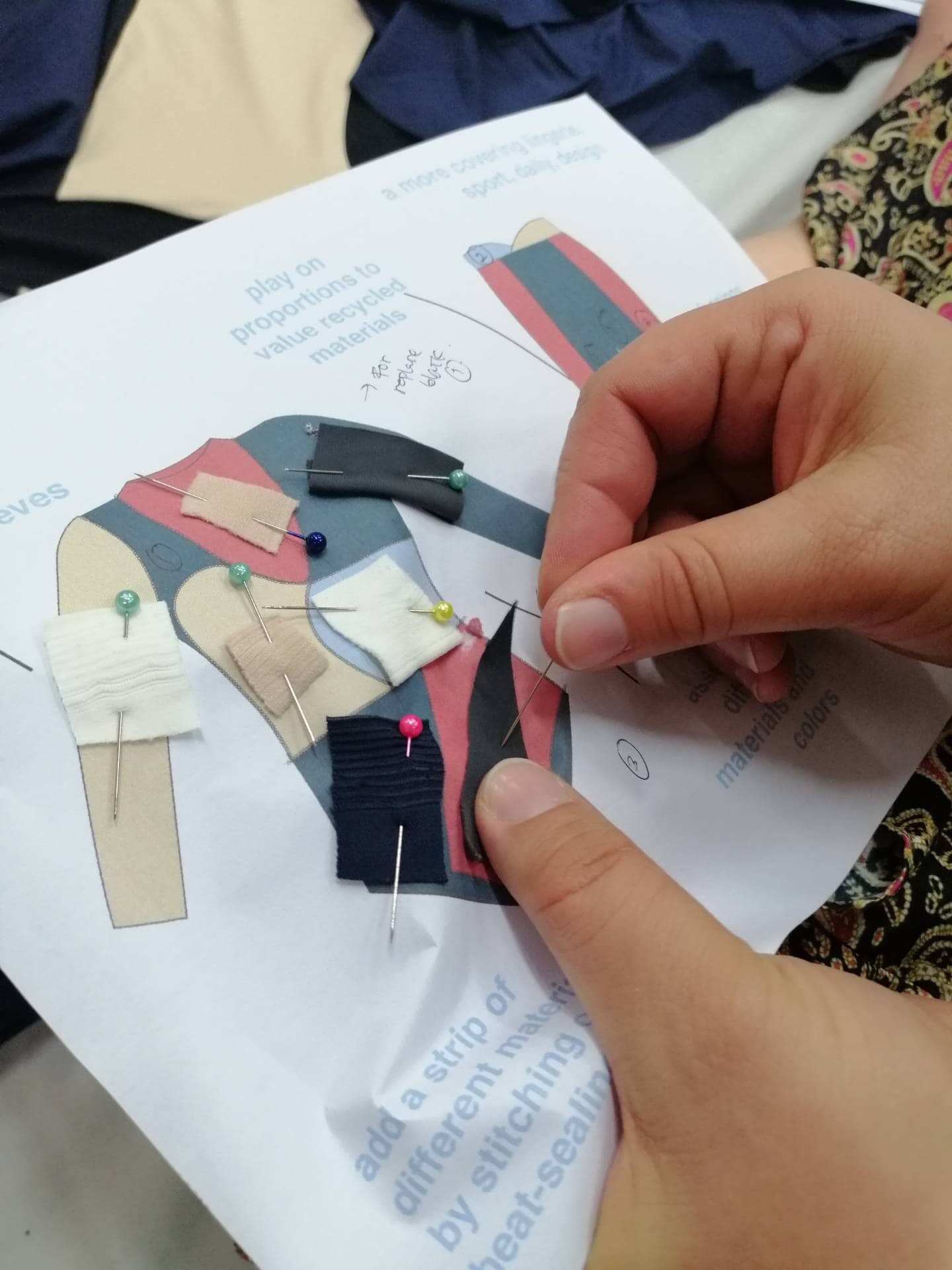

Considering the high value of the collected waste materials, Vanessa Causse (Director at Trend Union by Li Edelkoort) and Marina Chahboune (Founder of Closed Loop Fashion) in partnership with the product development team of PT. Busanaremaja Agracipta – a large manufacturer of intimates wear for the world’s leading brands jointly, took on the challenge to redesign the segregated waste materials into an upcycling collection of lingerie, swimwear and active-wear products. With this state-of-the-art collection, we redefined what ‘waste’ means to us by using upcycling as an alternative design strategy for product lifetime optimization and as an opportunity for innovation.

The waste materials were hand-picked at all four project-participating factories and in a second step segregated by color. Prior to the design process, color cards were defined, and a collection of 32 outfits and accessories sketched. In order to put the design into practice, either a design sketch was used as a basis or the garment was directly draped on the mannequin depending on the size and complexity of the available waste materials.

The upcycling collection was showcased in an exhibition and runway show during the Interfilière trade fair shows in Paris and Shanghai 2021 and received very positive response from the audience and press.

This initiative was conducted in the framework of a Private-Public-Partnership project for sustainable development, initiated by Eurovet Group, the organizer of the leading international trade show events for lingerie, swimwear and active-wear supply chains Interfilière, under the develoPPP.de Programme of the German Federal Ministry for Economic Cooperation and Development (BMZ) and in partnership with sequa gGmbH.

The project was conducted from 2018-2021 with four selected textile and lingerie manufacturers in Indonesia with an aim to integrate and promote sustainable and circular lingerie manufacturing through awareness creation, capacity building, knowledge transfer, practical implementations and participation in international trade fairs. During the project duration, all four factories improved their sustainable practices in regard to chemical management according to Zero-Discharge of Hazardous Chemicals (ZDHC), textile waste management, and work health and safety (WHS). The selected factories have participated at the Interfilière trade fair Hong Kong in 2019 and Interfilière Shanghai 2020 through the international digital platform Interfilière Connect.

Photo credit: EUROVET Interfilière; Closed Loop Fashion