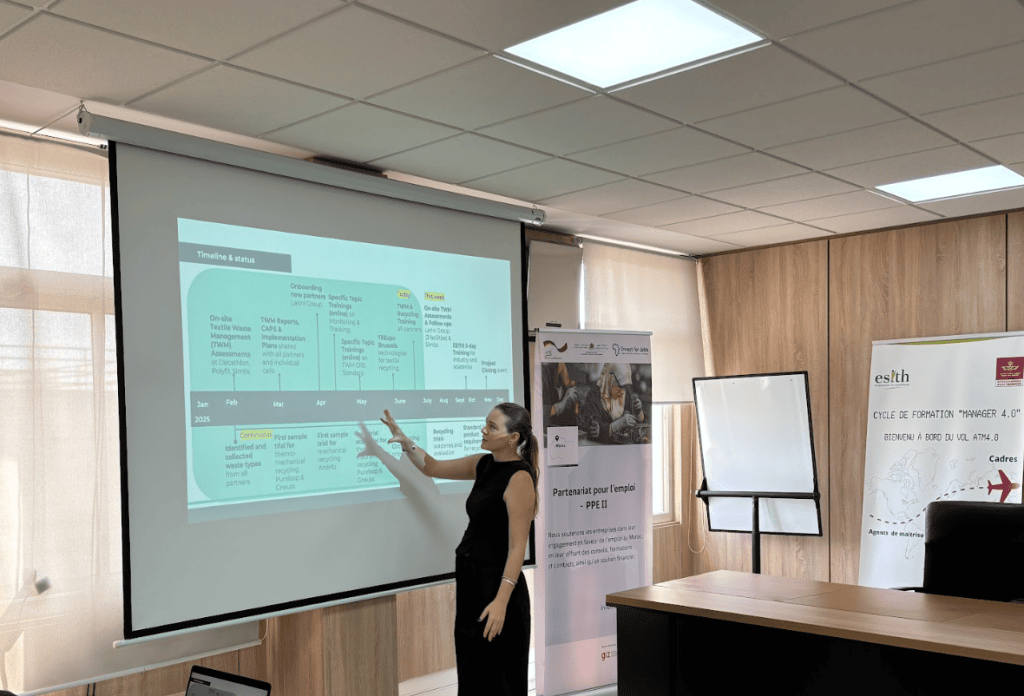

On June 16, 2025, Closed Loop Fashion and ESITH Casablanca held a one-day training in Casablanca, focusing on Textile Waste Management Systems & Recycling Opportunities. The session was part of the ongoing project “Development of a Circular Polyester Recycling System Between Private Sector Stakeholders in the Moroccan Textile Sector,” financed by Invest for Jobs special initiative and implemented by GIZ Morocco with support from the Federal Ministry for Economic Cooperation and Development (BMZ), in partnership with the Ministry of Industry and Trade in Morocco.

The training was designed specifically for project partners and brought together 15 participants from across the value chain, including Decathlon, Garment Factory Alliance, Larini Group, Cyclar, Simtis, and Polyfil. Alongside our team from Closed Loop Fashion and representatives from GIZ Morocco and ESITH, the group spent the day diving into key topics relevant for shaping the future of textile recycling in Morocco.

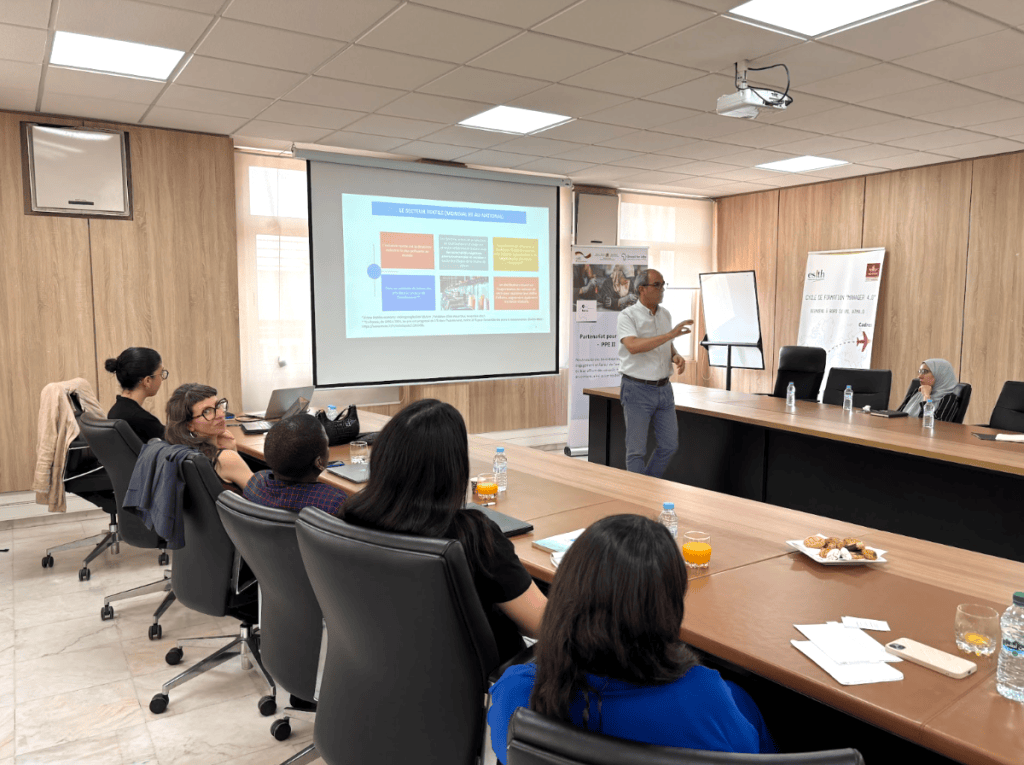

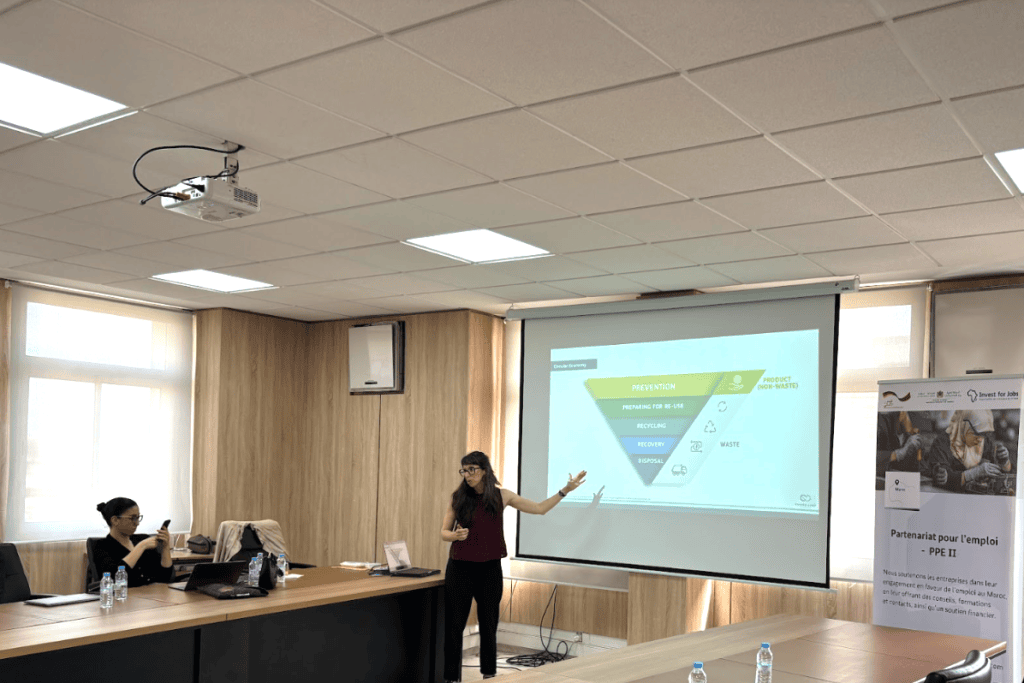

Throughout the day, participants explored key principles of the circular economy and better waste management practices, with a focus on how these apply to Morocco’s evolving polyester recycling landscape. The session covered:

- Circular Economy Principles and their relevance to textile production and post-industrial waste

- Challenges and Opportunities for textile producers and recyclers in transitioning to circular systems; global and local recycling context, an in-depth overview on recycling technologies

- Textile Waste Management Best Practices including an input session from a waste handler perspective

- EU Regulations and Legislation, highlighting how upcoming requirements will impact Moroccan exports and value chains and Morocco’s Waste Strategy

A significant portion of the training was dedicated to contextualizing recycling technologies and opportunities, both globally and locally. Discussion revolved around Morocco’s national waste strategy, existing polyester waste streams, and the potential for scaling recycling solutions through collaborative infrastructure development.

The training also offered a practical introduction to textile waste management principles and best practices, aiming to equip participants with actionable tools to pilot and improve internal systems at factory level. Closed Loop Fashion introduced four core aspects of textile waste mapping to support improved waste management in factories:

- Waste prevention and reduction: Identify where waste is generated and categorize it by type, material, and volume.

- Preparation for reuse: Collect, sort, and store waste for potential processing or recycling.

- Reuse: Allocate sorted waste to appropriate recycling options, either in-house or with external partners.

- Tracking and monitoring: Record each stage of the waste mapping process to enable better decision-making and continuous improvement.

By integrating these steps into factory SOPs, facilities can set clear targets, reduce waste generation, and shift toward higher-value disposal methods such as reuse, recycling, upcycling, and downcycling.

This training is a core component of the broader polyester recycling initiative, which aims to build a viable, scalable circular economy model for Morocco’s textile sector. All participants were awarded a certificate to acknowledge their involvement in the program. As the technical partner, Closed Loop Fashion is proud to support this process through capacity building, industry alignment and on-the-ground implementation.