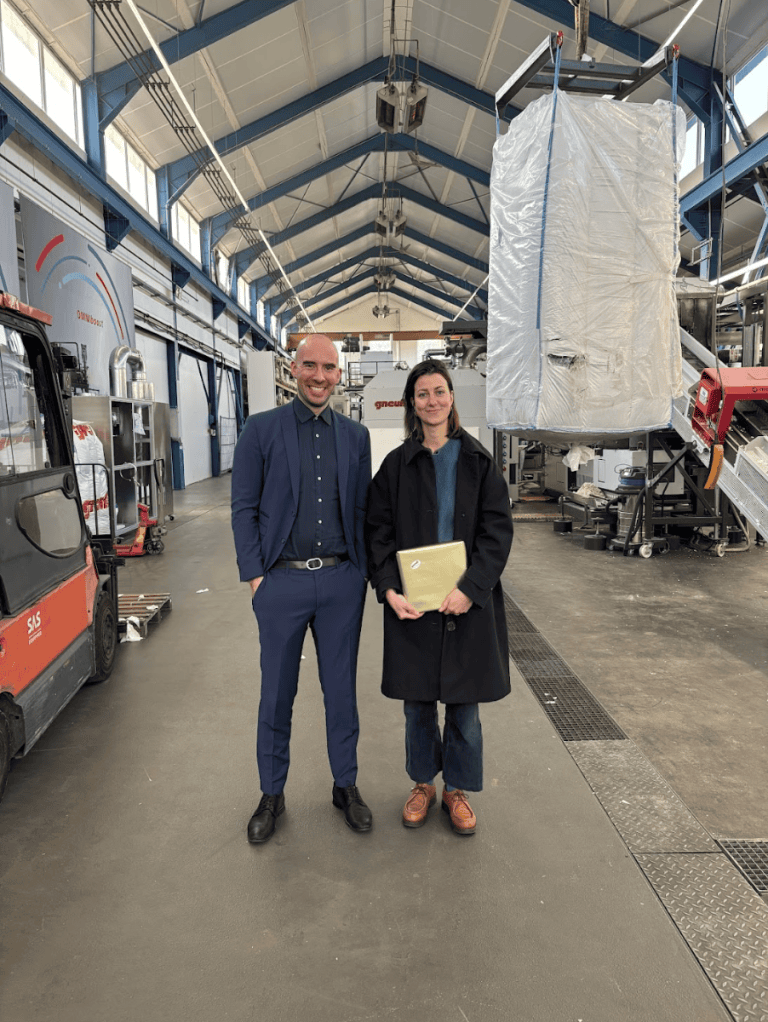

On 22 January 2026, the Closed Loop Fashion team visited the trial lab centre of Gneuss in Bad Oeynhausen, Germany. This trial is part of a broader series of tests to identify the most suitable textile-to-textile recycling technologies for different polyester waste streams in Morocco. Gneuss is a German engineering company providing advanced recycling technologies that enable the conversion of plastic and textile waste into high-quality recycled pellets.

The trials focused on 100% monomaterial polyester cutting waste collected and sorted by ZITECO in Morocco, in which the material was shipped to Germany specifically for testing as part of this trial.

Testing textile-to-textile recycling potential

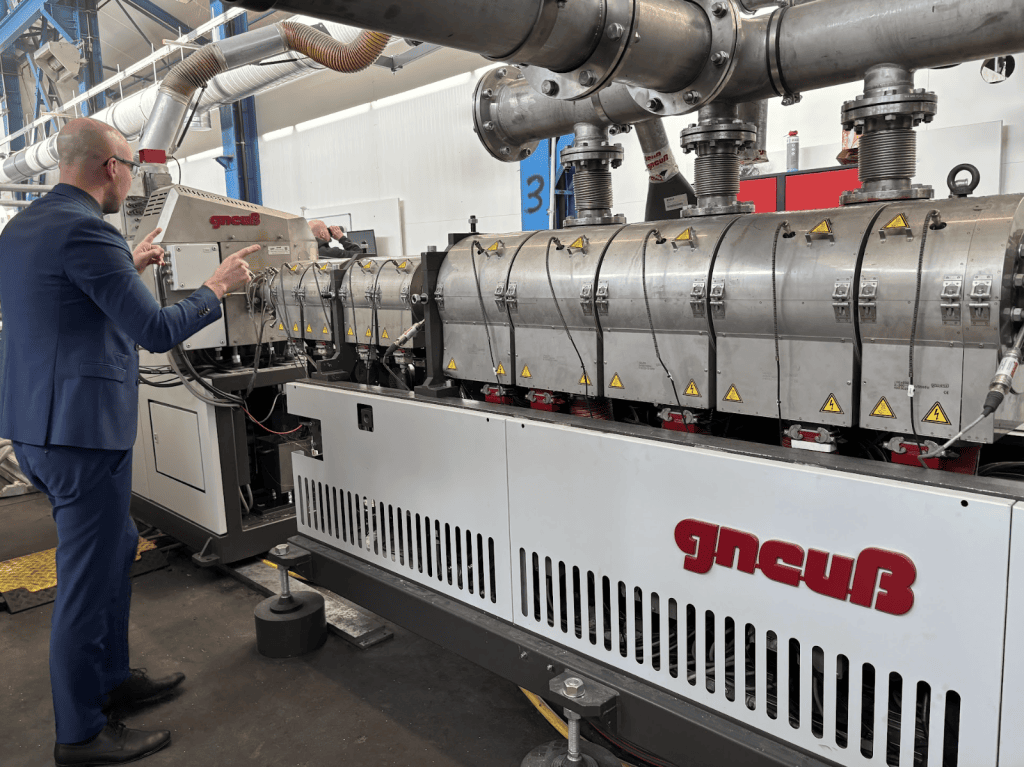

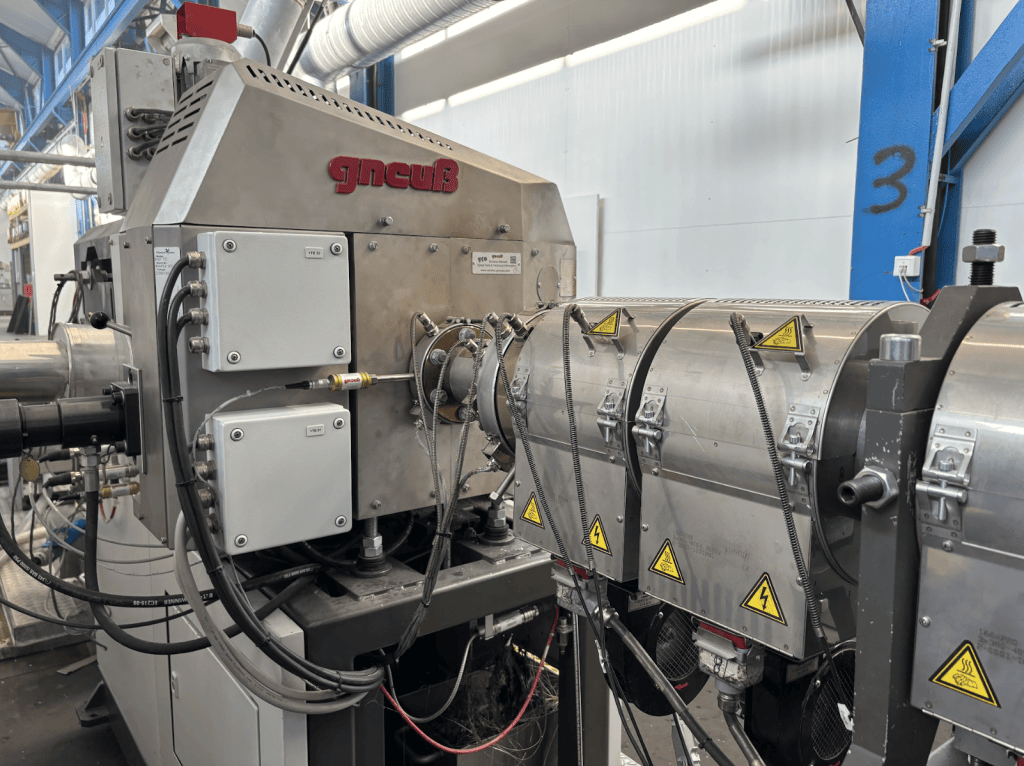

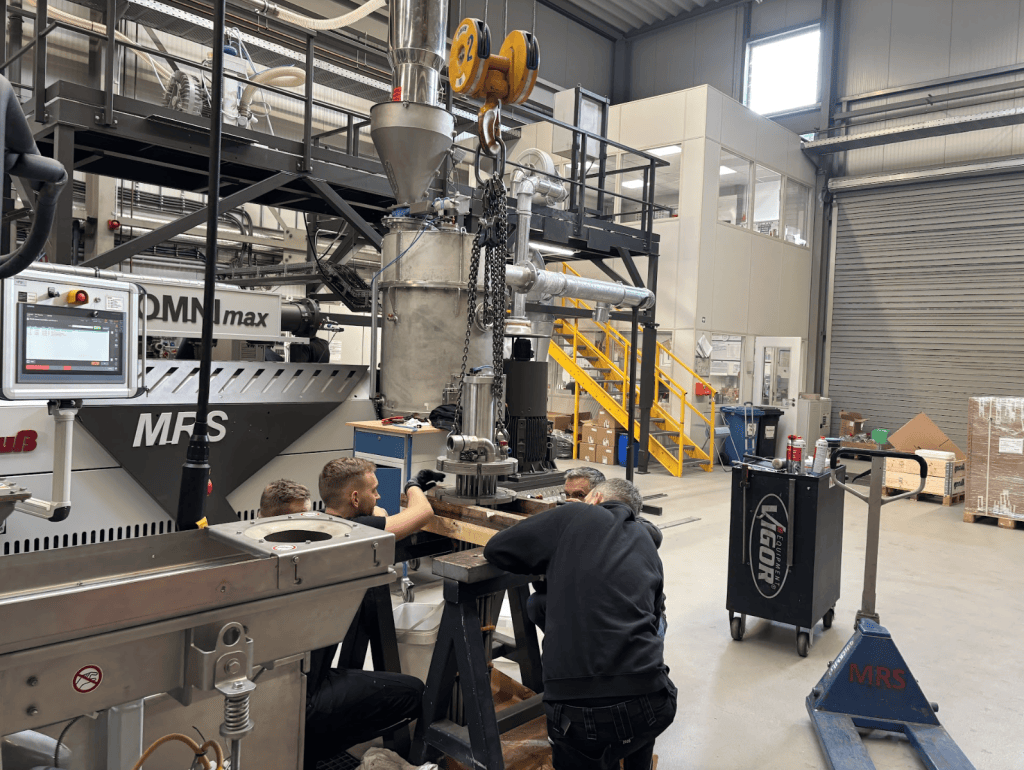

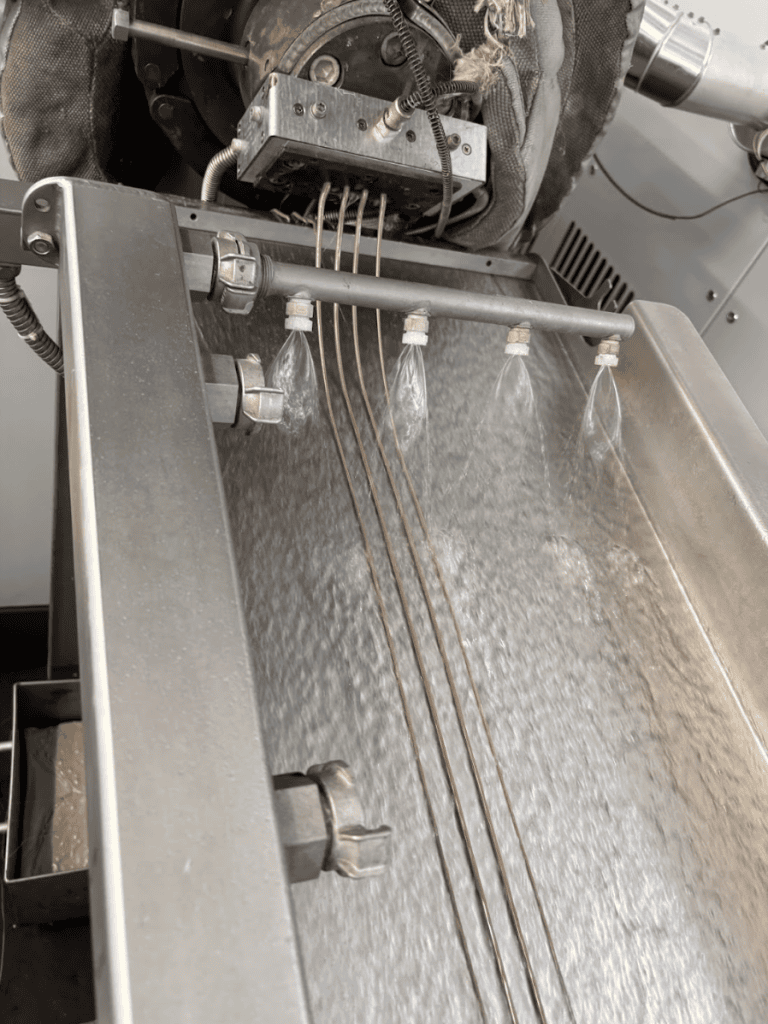

The purpose of the visit at Gneuss was to better understand whether post-industrial polyester cutting waste is suitable for thermo-mechanical recycling, a process that combines mechanical preparation with melting and regranulation to produce recycled polyester pellets.

The trials showed that the material can be successfully converted into rPES (recycled polyester) pellets. At the same time, the results clearly confirmed how strongly the output quality depends on the quality of the input material. Feedstock purity, consistency as well as pre-treatment and finishing applications all play a key and decisive role in the process.

One of the strongest takeaways was the impact of contamination. Even small amounts of non-textile materials, such as paper or mixing with other fibre types, directly affect polymer quality and intrinsic viscosity. In this context, the material collected and sorted by ZITECO stood out for its high level of segregation, with no contamination from impurities or textiles of other material compositions. This made stable processing possible and highlighted how critical good waste segregation at factory level is for any textile-to-textile recycling pathway.

Why consistency and transparency matter

Beyond technical feasibility, the trials also illustrated how challenging it is to guarantee consistent output quality when working with textile waste. Each supply of waste bales can produce different outcomes, depending on factors such as finishing applications or substances used during production (eg. spinning oils and texturising agents). These variations can influence polymer performance during recycling and are often difficult to identify or troubleshoot at a later stage.

This reflects the importance of transparency and close collaboration across the entire supply chain, from manufacturing to waste handling and recycling companies. Without shared information and aligned practices, scaling textile-to-textile recycling remains challenging.

Building evidence for circular polyester in Morocco

Thermo-mechanical recycling is a well-established route for recycling PET waste, but the success depends heavily on feedstock quality, transparency and process control. At present, Morocco does not yet have an industrial-scale thermo-mechanical recycling line dedicated to textile waste.

Pilot trials such as this one are an important step in building a realistic understanding of what works, under which conditions, and where the remaining gaps are. They help translate circularity ambitions into practical insights that can guide future investment, infrastructure development and policy support.

Closed Loop Fashion would like to warmly thank the Gneuss team, for carefully conducting the trials, openly sharing their technical learnings and engaging in an honest exchange on the opportunities and limitations of textile-to-textile recycling for the apparel industry. These trials mark another concrete step in advancing applied, evidence-based solutions for polyester recycling systems in Morocco.

This activity is part of the project “Development of a Circular Polyester Recycling System Between Private Sector Stakeholders in the Moroccan Textile Sector” conducted on behalf of the German technical development corporation, the Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH, on behalf of the German Federal Ministry of Economic Cooperation and Development (BMZ) in the framework of the Special Initiative “Decent Work for a Just Transition” (Invest for Jobs).